Lünendonk White Paper 2021

Download the white paper now!

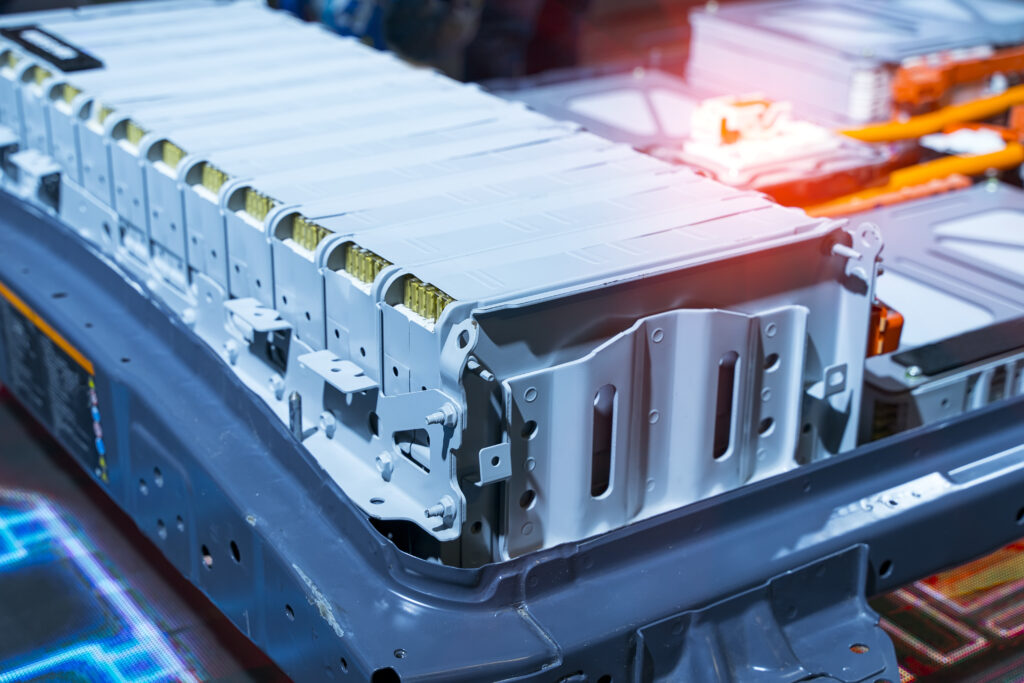

What contribution can external service providers make in the transformation of the automotive industry towards battery-electric mobility?

Find out more in the Lünendonk publication produced in collaboration with Leadec!

In this paper you will learn more about the following contents:

-

Transformation of production processes

-

Overview of battery production in Germany and Europe

-

Production requirements in the factory

-

Technical services for battery production and assembly

-

Interview with Dr. Christoph Jaschinski (Leadec)

Modern factories are organized according to a strong division of labor: materials, components, suppliers, and various production processes, as well as logistics must be closely coordinated. A large number of external service providers are involved in the assembly, logistics and maintenance of production facilities. In the course of the shift in production to a high degree of automation and digitalization, the requirements are changing not only for the production process, but also for the service providers involved.

This white paper presents the essential requirements for external technical service providers involved in the production of components and vehicles with high-voltage batteries. In particular, the effects of technical progress, the economic cycle of high-voltage batteries, the changed requirements for employees and the quality requirements are addressed. The paper is designed as a position paper that is intended to serve as an orientation for companies and observers for a more in-depth examination of the topic.

Available since 15 April 2021 | PDF | free of charge

Your points of contact

Thomas Ball

Partner, Lünendonk & Hossenfelder GmbH

„Electromobility has established itself and is here to stay. This makes it clear: The automotive industry is undergoing the greatest transformation since the introduction of assembly line production more than 100 years ago.”

Dr. Christoph Jaschinski

Senior Vice President, Leadec Holding BV & Co. KG

„With new manufacturing, assembly and testing technologies, the trend towards smart manufacturing and therefore smart services will continue to grow, especially in the production of battery cells and modules — a focus for modern industrial service providers.”

The partners